Tel: 01763 262333

Specific Surface Area (BET Area) by Nitrogen and Krypton Adsorption

The

surface

area

of

a

material

will

often

profoundly

affect

its

behaviour

and

performance,

whatever

its

application.

Therefore,

understanding

surface

area

is

commonly

a

critical

parameter

when

considering

materials

procurement,

processing

and

fabrication,

assessment

of

performance

and

investigation

of

atypical

performance

and

product

failure.

Specific

surface

area

can

be

used

to

directly

determine

many

factors,

such

as

reactivity,

adsorption

capacity,

dissolution

rate,

electrochemical

and

catalytic

performance

and

sintering

ability.

Specific

surface

area

is

commonly

measured

using

the

BET

(Brunauer-Emmett-Teller)

method

applied

to

a

gas

adsorption

isotherm.

For

the

majority

of

materials

nitrogen

gas

adsorption

is

applied,

which

can

be

combined

with

the

more

extensive

full

isotherm

analysis

to

determine

pore

size

and

volume

characteristics.

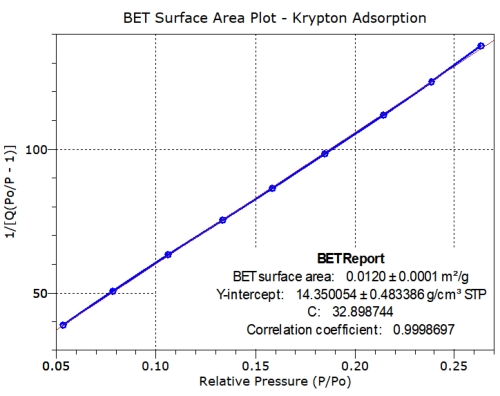

However,

for

very

low

surface

area

materials

krypton

gas

adsorption

becomes

more

reliable

and

can

be

used

to

determine

surface area very close to the geometric area of a non-porous sample material.

The

combination

of

nitrogen

and

krypton

adsorption

methods

provides

MCA

Services

with

the

capability

of

accurately

measuring

materials

with

specific surface areas below 0.05 m

2

/g to over 2000 m

2

/g.

Key Applications

Surface area directs the interaction of a solid with other media

Surface Area is a critical factor for:

Material selection

Processing and fabrication method development

Routine QC of raw materials and finished products

Performance assessment of products and materials

Identification of performance issues

Product capacity and life-cycle

Product regeneration

Assessment of chemical activity

Comprehensive degassing options to cover most sample materials

Alternative adsorbate options

At

MCA

Services

sample

analysis

is

undertaken

using

our

Micromeritics

TriStar

3030

plus

instrument,

which

utilises

the

volumetric

method

of

gas

adsorption.

Before

analysis

it

is

essential

that

samples

are

fully

dried

and

degassed

as

extraneous

substances

will

provide

an

artificially

low

surface

area

value.

We

have

a

comprehensive

range

of

degassing

options,

capable

of

temperatures

in

the

range

ambient

to

400

°C

under

dynamic

vacuum

or

flowing

inert

gas.

We

can,

therefore,

prepare

virtually

any

sample

material

on-site

immediately

prior

to

analysis,

which

ensures the most accurate and reliable measurements are obtained.

At

MCA

Services

sample

analysis

is

undertaken

using

our

Micromeritics

TriStar

3030

plus

instrument,

which

utilises

the

volumetric

method

of

gas

adsorption.

Before

analysis

it

is

essential

that

samples

are

fully

dried

and

degassed

as

extraneous

substances

will

provide

an

artificially

low

surface

area

value.

We

have

a

comprehensive

range

of

degassing

options,

capable

of

temperatures

in

the

range

ambient

to

400

°C

under

dynamic

vacuum

or

flowing

inert

gas.

We

can,

therefore,

prepare

virtually

any

sample

material

on-site

immediately

prior

to

analysis,

which

ensures the most accurate and reliable measurements are obtained.

Analytical Options and Highlights

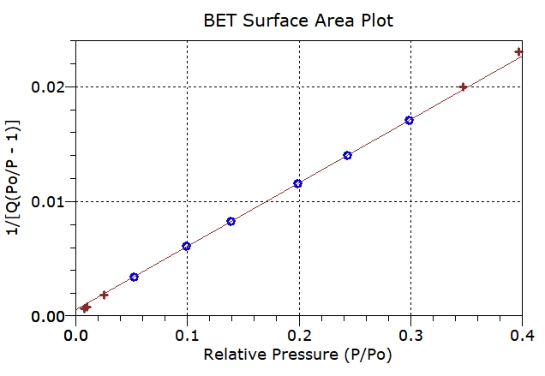

Multi-point BET surface area measurement

Single-point BET surface area option available

N

2

and Kr adsorption options cover virtually any surface area

Reliable low pressure data applicable to highly micro-porous samples

Comprehensive sample preparation and degassing options

Highly adaptable methods to suit and match historical data

Numerical and graphical reporting format

Options to extend to full isotherm analysis

At

MCA

Services

we

have

decades

of

experience

in

the

analysis

and

characterisation

of

materials

and

are

always

happy

to

discuss

specific

samples

and

applications.

Our

expertise

ensures

that

the

most

appropriate

analytical

test,

or

combination

of

tests,

are

selected

for

your

particular

sample,

application

and

requirements.

We

also

provide

assistance

with

the

interpretation

of

results

and

more

information

about

these

analytical options and the background operation and theory can be found on our YouTube channel.

Specific Surface Area (BET Area)

Nitrogen and Krypton Gas Adsorption

The

surface

area

of

a

material

will

often

profoundly

affect

its

behaviour

and

performance,

whatever

its

application.

Therefore,

understanding

surface

area

is

commonly

a

critical

parameter

when

considering

materials

procurement,

processing

and

fabrication,

assessment

of

performance

and

investigation

of

atypical

performance

and

product

failure.

Specific

surface

area

can

be

used

to

directly

determine

many

factors,

such

as

reactivity,

adsorption

capacity,

dissolution

rate,

electrochemical

and

catalytic

performance

and

sintering

ability.

Specific

surface

area

is

commonly

measured

using

the

BET

(Brunauer-Emmett-

Teller)

method

applied

to

a

gas

adsorption

isotherm.

For

the

majority

of

materials

nitrogen

gas

adsorption

is

applied,

which

can

be

combined

with

the

more

extensive

full

isotherm

analysis

to

determine

pore

size

and

volume

characteristics.

However,

for

very

low

surface

area

materials

krypton

gas

adsorption

becomes

more

reliable

and

can

be

used

to

determine

surface

area

very

close to the geometric area of a non-porous sample material.

The

combination

of

nitrogen

and

krypton

adsorption

methods

provides

MCA

Services

with

the

capability

of

accurately

measuring

materials

with

specific

surface

areas

below

0.05

m

2

/g

to over 2000 m

2

/g.

Key Applications

Surface area directs interactions of solids with other media

Surface Area is a critical factor for:

Material selection

Processing and fabrication method development

Routine QC of raw materials and finished products

Performance assessment of products and materials

Identification of performance issues

Product capacity and life-cycle

Product regeneration

Assessment of chemical activity

Comprehensive degassing options

Alternative adsorbate options

At

MCA

Services

sample

analysis

is

undertaken

using

our

Micromeritics

TriStar

3030

plus

instrument,

which

utilises

the

volumetric

method

of

gas

adsorption.

Before

analysis

it

is

essential

that

samples

are

fully

dried

and

degassed

as

extraneous

substances

will

provide

an

artificially

low

surface

area

value.

We

have

a

comprehensive

range

of

degassing

options,

capable

of

temperatures

in

the

range

ambient

to

400

°C

under

dynamic

vacuum

or

flowing

inert

gas.

We

can,

therefore,

prepare

virtually

any

sample

material

on-site

immediately

prior

to

analysis,

which

ensures

the

most

accurate

and reliable measurements are obtained.

Analytical Options and Highlights

Multi-point BET surface area measurement

Single-point BET surface area option available

N

2

and Kr adsorption options for virtually any surface area

Low pressure data applicable to micro-porous samples

Comprehensive sample preparation and degassing options

Highly adaptable methods to suit and match historical data

Numerical and graphical reporting format

Extension to full isotherm analysis

At

MCA

Services

we

have

decades

of

experience

in

the

analysis

and

characterisation

of

materials

and

are

always

happy

to

discuss

specific

samples

and

applications.

Our

expertise

ensures

that

the

most

appropriate

analytical

test,

or

combination

of

tests,

are

selected

for

your

particular

sample,

application

and

requirements.

We

also

provide

assistance

with

the

interpretation

of

results

and

more

information

about

these

analytical

options

and

the

background

operation

and

theory

can

be

found

on

our

YouTube channel.